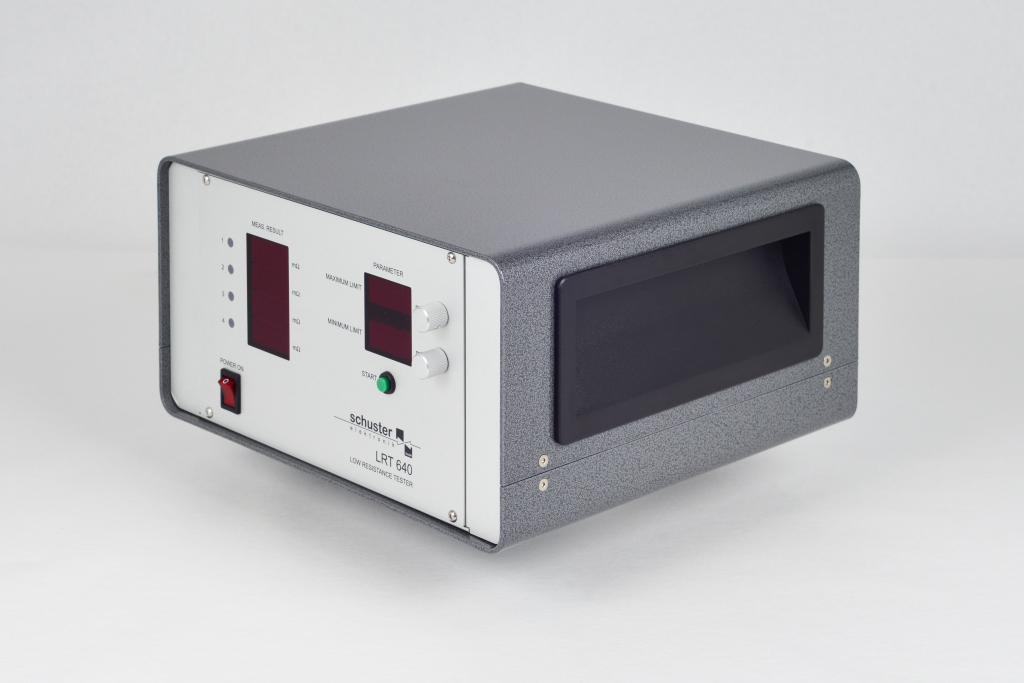

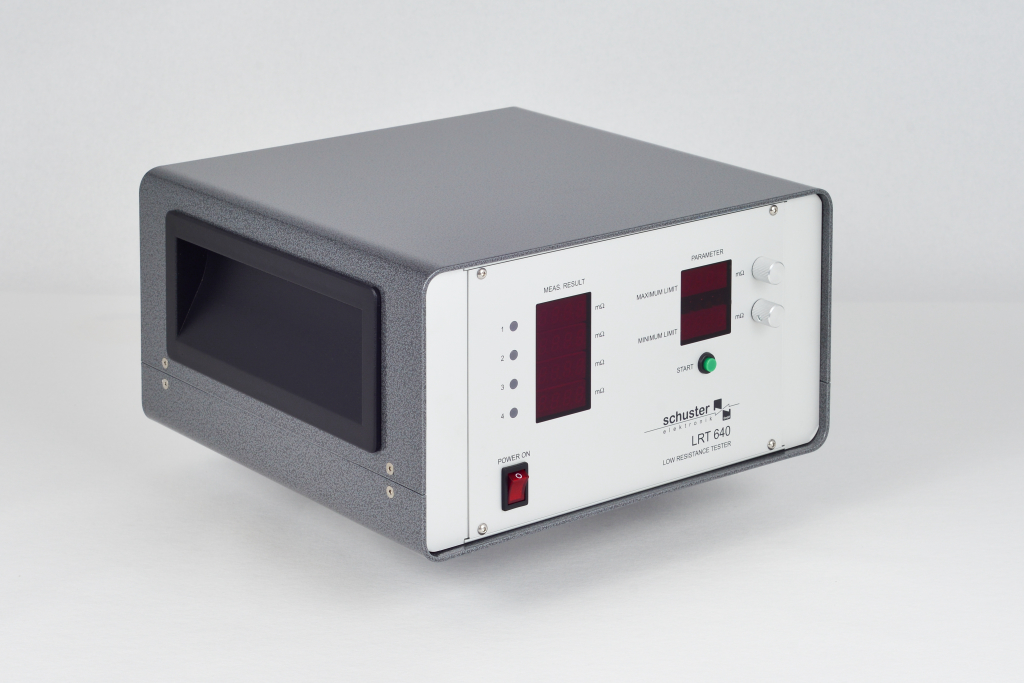

LRT 640 - Low Resistance Tester

- Integration into an automatic system via PLC- and Ethernet-interface

- Manually testing of components in production and quality assurance

- Resistance measurement at up to 4 measuring points at the same time

- Measuring range 1 up to 100 mW

- Contact test before each measurement

- Kelvin contact ratio metric measurement method including thermos voltage compensation

- PLC- and Ethernet- interface

- Short measurement duration approx. 50 ms / measuring point

Merkmale

The instrument LRT 640 is used to measure small electric resistors in production lines, e. g. fuses.

The LRT 640 has a PLC-interface to be integrated into the sequencing of the production as well as an Ethernet-interface to acquire the production data.

The instrument measures up to 4 resistors of the same kind simultaneously.

A measurement can be started via PLC or pushing the start-button. Every activated measuring point is measured in the following way:

Contact test: The resistance of the cable and the contact resistance of Rx are measured using a test current of approx. 100 mA.

Zero measurement: During the idle state (no current) thermo-electric voltages may occur and affect the resistance test. Therefore a reference value is determined to correct the measurement results if necessary.

Resistance test: The measurement current (0.5 A) through the DUT and the RREF is turned on and the resistance value is determined out of the ratio of the voltages (ratio metric measuring).

The result is compared to the minimum and the maximum value and a “good”/”fail”-decision is made. Every measuring point has its own LED lamps to show the “good”/”fail”-result.